Agriton Fermenter

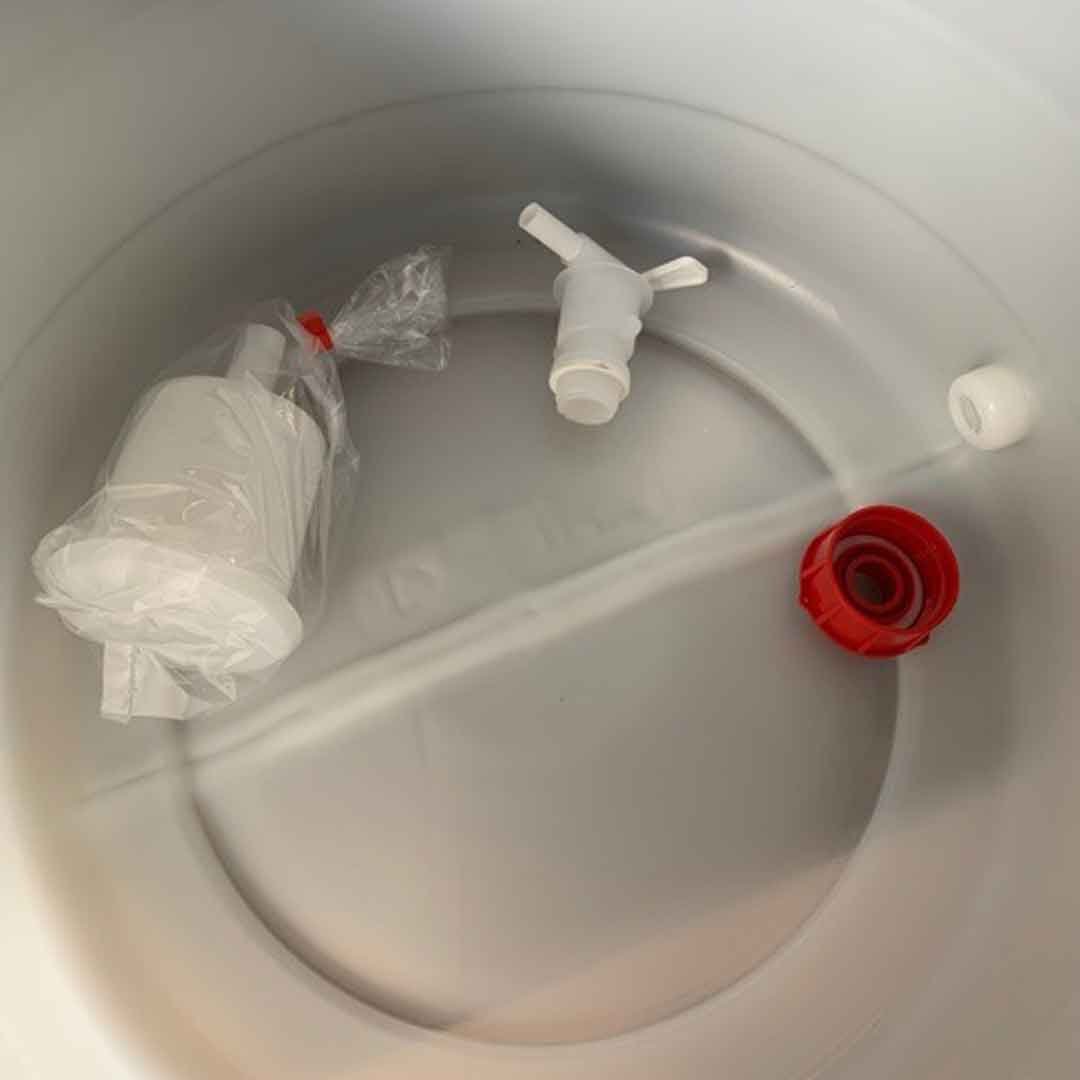

The EM Activator enhances the activation process of the base solution (EM-1®) with A+ Sugar Cane Molasses, creating EM-A, also known as Actiferm. The fermenting vessel includes a heating element, pressure release valve and all the taps you will need. As the microbes within EM-1 are facultative, no bubbling is required.

For optimal results, get the water up to temperature before adding EM-1 and never use mains water. Mains water contains chlorine which will kills the microbes. Rain water, spring or borehole water is great. If you do not have access to that then you can de-chlorinate water by letting the chlorine evaporate for a period of time.

The EM Activator enhances the activation process of the base solution (EM-1®) with A+ Sugar Cane Molasses, creating EM-A, also known as Actiferm. The fermenting vessel includes a heating element, pressure release valve and all the taps you will need. As the microbes within EM-1 are facultative, no bubbling is required.

For optimal results, get the water up to temperature before adding EM-1 and never use mains water. Mains water contains chlorine which will kills the microbes. Rain water, spring or borehole water is great. If you do not have access to that then you can de-chlorinate water by letting the chlorine evaporate for a period of time.

The EM Activator enhances the activation process of the base solution (EM-1®) with A+ Sugar Cane Molasses, creating EM-A, also known as Actiferm. The fermenting vessel includes a heating element, pressure release valve and all the taps you will need. As the microbes within EM-1 are facultative, no bubbling is required.

For optimal results, get the water up to temperature before adding EM-1 and never use mains water. Mains water contains chlorine which will kills the microbes. Rain water, spring or borehole water is great. If you do not have access to that then you can de-chlorinate water by letting the chlorine evaporate for a period of time.

The EM Activator optimizes the activation of the stock solution (EM-1®), by A+ (cane sugar molasses), forming EM-A. It allows a stable anaerobic fermentation and to the heating element stabilizing the temperature.

30L – Activates 1.5L EM-1 & 1.5L Molasses

60L – Activates 3L EM-1 & 3L Molasses

120L – Activates 6L EM-1 & 6L Molasses

220L – Activates 12L EM-1 & 12L Molasses

In the realm of agricultural and animal husbandry innovations, biological products play a pivotal role in shaping a sustainable future. However, the efficacy of these products varies, and a crucial aspect lies in understanding the capabilities of the microorganisms they contain. These microorganisms must excel at:

Surviving and Thriving: Flourishing in the specific application environment.

Waking Up and Activating: Transitioning from a dormant state to an active, beneficial one.

Multiplying with Purpose: Proliferating to achieve desired effects.

Many contemporary biological products undergo industrial processes, involving chemical treatments and freeze-drying. This approach mandates that all cells within the product progress through these stages before imparting any impact upon application.

EM•1®: A Natural Paradigm Shift

EM•1® stands as a groundbreaking solution, distinguished from other biological products in the UK. What sets EM•1® apart is its industrialization process adhering to natural principles, preserving microorganisms in their innate state.

Going beyond the three survival stages, EM•1® introduces an extra dimension—metabolite production, featuring natural substances that support life. The key lies in a controlled activation process.

EM•1® houses dormant microorganisms in their natural state, and activating them is a straightforward process. Over four decades, the EM Research Organization (EMRO) has globally standardized this activation process, ensuring peak performance and consistency with EM® Technology.

During a 7-day activation period, EM•1® not only reaches its full potential but also becomes 100% free from potential contamination by pathogenic microorganisms. This distinction makes EM•1® the safest biological product on the market, certified organic and meeting rigorous standards.

The controlled activation process bypasses survival stages, creating a formidable biochemical barrier against pathogenic microbes. Simultaneously, it enriches the solution with potent amino acids essential for plant growth, paving the way for a sustainable and thriving agricultural future.

Activation Instructions:

5% Concentrated EM-1® solution

5% Molasses

90% Water

Note: Deviating from these activation instructions may result in suboptimal performance and is not the responsibility of Agriton or its partners. Refer below for detailed guidelines on how to activate EM•1® properly.